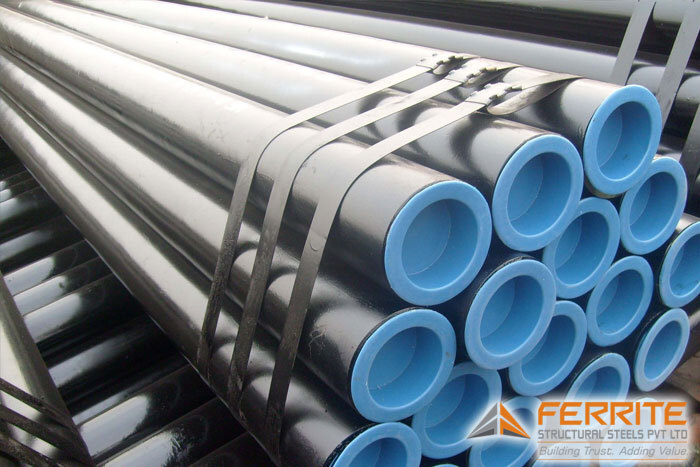

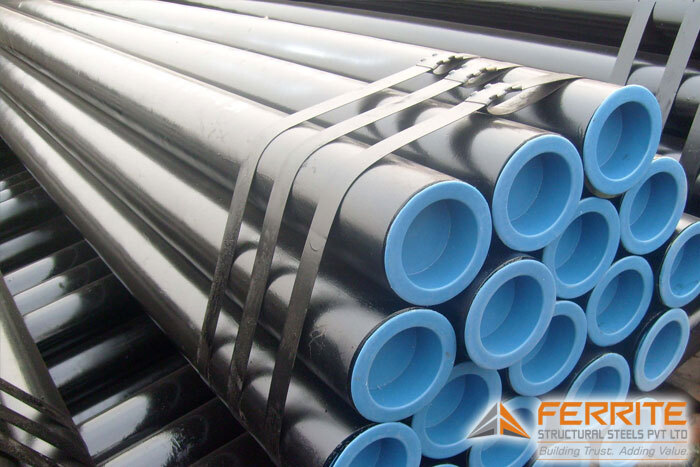

Seamless Tube

Product Details:

- Diameter 4 inches

- Recyclable non-recyclable

- Product Name Steel Products

- Steel Type Stainless Steel

- Steel Product Type Steel Pipes

- Thickness 1 inch-2 inch

- Shape Customized

- Click to View more

Seamless Tube Price And Quantity

- 1 Ton Kilograms

- 65 INR/Kilograms

Seamless Tube Product Specifications

- 1 inch-2 inch

- Steel Products

- Stainless Steel

- Steel Pipes

- Other

- non-recyclable

- 4 inches

- 4 inches

- Steel , Silver

- Customized

- Painted, galvanized, or standard mill finish

- Construction

Seamless Tube Trade Information

- Cash Advance (CA) Cash in Advance (CID) Cheque

- 1 Kilograms Per Week

- 7 Days

- Standard, As per requirement,

- All India

- We are certified under the ISO 9001:2015 standard, with authorized distributor of Memorandum of Understanding (MoU) customer of the Steel Authority of India Ltd. (SAIL).

Product Description

The production of seamless tubes typically involves the rotary piercing method. In this process, a solid metal billet is heated and pierced to create a hollow shell. This shell is then elongated and shaped through rolling or extrusion to achieve the desired dimensions and properties. The absence of weld seams ensures uniformity in strength and structure throughout the tube.

Key Features:

-

Enhanced Strength: The seamless nature of these tubes eliminates the potential weak points associated with welded seams, providing superior mechanical properties.

-

Uniform Structure: Consistent composition and dimensions throughout the tube ensure reliable performance under various conditions.

-

Corrosion Resistance: Particularly in stainless steel variants, seamless tubes offer excellent resistance to corrosion, making them suitable for harsh environments.

-

-

When selecting seamless tubes for a project, it's essential to consider factors such as material composition, dimensions, and the specific requirements of the application. In summary, seamless tubes provide a combination of strength, uniformity, and versatility, making them a preferred choice in numerous industrial applications.

-

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS