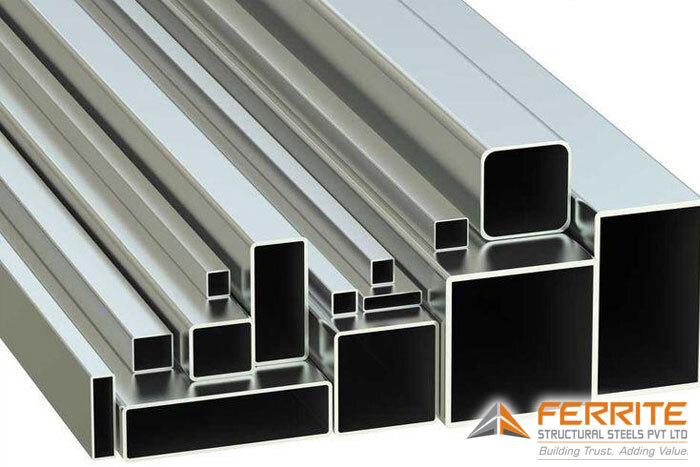

Pressure Pipes

Product Details:

- Recyclable non-recyclable

- Product Name Steel Products

- Steel Type Mild Steel

- Steel Product Type Steel Pipes

- Thickness 3 mm

- Shape Customized

- Steel Standard Other

- Click to View more

Pressure Pipes Price And Quantity

- 1 ton Kilograms

- 55 INR/Kilograms

Pressure Pipes Product Specifications

- Steel Pipes

- Steel Products

- 3 mm

- Customized

- Stainless Steel, silver

- Construction

- Mild Steel

- Other

- non-recyclable

- as per requirement

- Painted, galvanized, or standard mill finish

Pressure Pipes Trade Information

- Standard, As per requirement,

- All India

- We are certified under the ISO 9001:2015 standard, with authorized distributor of Memorandum of Understanding (MoU) customer of the Steel Authority of India Ltd. (SAIL).

Product Description

High Pressure Tolerance: Engineered to withstand and safely convey substances at high pressures.

Durability: Resistant to wear, abrasion, and impact, ensuring longevity in demanding environments.

Chemical Resistance: Capable of resisting degradation from chemicals and corrosive substances.

Flexibility: Facilitates ease of installation and adaptability to various conditions.

Leak Prevention: Offers high sealing integrity to prevent leaks.

Materials Used:

-

Steel: Commonly used for its strength and durability, with grades like A and B offering varying tensile strengths.

-

PVC (Polyvinyl Chloride): Lightweight and resistant to corrosion, suitable for applications where operating temperatures do not exceed 140F.

-

HDPE (High-Density Polyethylene): Known for flexibility and chemical resistance, often used in geothermal applications.

-

Reinforced Thermoplastic Pipes (RTP): Combines thermoplastic materials with reinforcement layers, offering high-pressure tolerance and corrosion resistance.

Applications:

-

Oil and Gas Industry: Utilized in transporting hydrocarbons and other fluids under high pressure.

-

Power Generation: Employed in systems like boilers and heat exchangers to handle pressurized steam and water.

-

Manufacturing: Used in hydraulic and pneumatic systems to transmit power through pressurized fluids.

Selecting the appropriate pressure pipe involves considering factors such as material compatibility, pressure rating, temperature range, and environmental conditions to ensure safety and efficiency in your specific application.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS