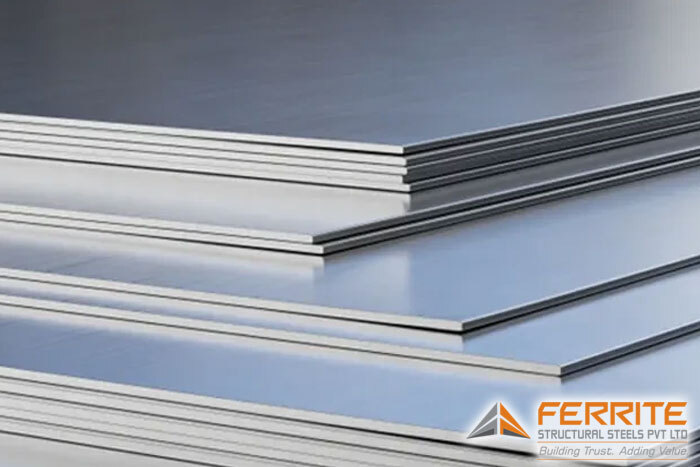

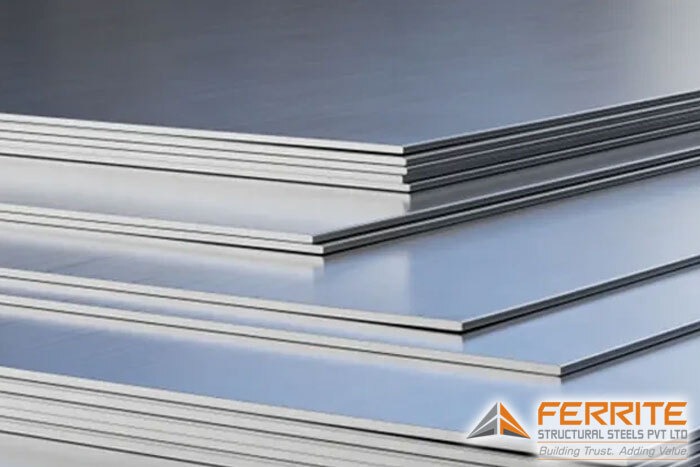

HR sheets

Product Details:

- Coating Type Hot-rolled

- Recyclable non-recyclable

- Product Name Steel Products

- Steel Type Mild Steel

- Steel Product Type Steel Sheets

- Grade steel

- Thickness 3 mm to 100 mm

- Click to View more

HR sheets Price And Quantity

- 61 INR/Kilograms

- 1 Ton Kilograms

HR sheets Product Specifications

- steel

- Mild Steel

- Steel Sheets

- Steel

- 3 mm to 100 mm

- Hot-rolled

- Customized

- 23.55 to 785 kg

- Steel Products

- Other

- Hot-rolled

- non-recyclable

- 28.3 to 1884 mm

- Steel , Silver

HR sheets Trade Information

- Cash Advance (CA) Cash in Advance (CID) Cheque

- Standard, As per requirement,

- All India

- Ferrite Structural Steels Pvt Ltd, established in 2004 in Mumbai, India, is a privately held company specializing in the production and supply of high-quality special steel structures. With a lineage of over 30 years in the steel industry, we have forged strong relationships with leading steel manufacturers and suppliers across India.

Product Description

HR Sheets (Hot Rolled Sheets)

HR Sheets, or Hot Rolled Sheets, are steel sheets that are processed using the hot rolling method. During this process, the steel is heated above its recrystallization temperature and then rolled into thin sheets. This method allows for easy shaping and forming of the sheets, resulting in products that are suitable for various industrial and structural applications.

Key Features:

-

High Strength and Durability: Offers good tensile strength, making them suitable for heavy-duty applications.

-

Good Formability: Can be easily bent, shaped, and fabricated.

-

Affordable: Cost-effective compared to cold-rolled sheets, making them ideal for bulk manufacturing.

-

Smooth Surface Finish: Although slightly rougher than cold-rolled sheets, the surface is generally acceptable for many structural applications.

-

Versatile Applications: Used across numerous industries, including construction, automotive, and manufacturing.

Applications:

-

Construction: Structural frameworks, roofing, wall panels, and bridges.

-

Automotive Industry: Manufacturing of frames, chassis, and other structural components.

-

Fabrication: General fabrication work, including tanks, containers, and machinery parts.

-

Shipbuilding: Hulls, decks, and bulkheads.

-

Pipelines: Oil and gas industries for pipes and fittings.

Advantages:

-

Cost-Effective: Economical choice for structural and heavy-duty applications.

-

High Weldability: Can be easily welded without compromising strength.

-

Customization: Available in various sizes, thicknesses, and grades to suit different requirements.

-

Easy Fabrication: Can be cut, bent, or shaped to meet specific needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free