High Strength Low Alloy Sheets

Product Details:

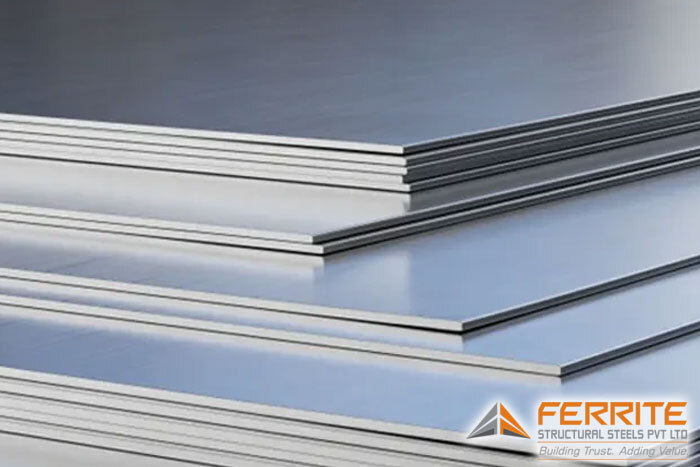

- Coating Type Painted, galvanized, or standard mill finish

- Product Name Steel Products

- Steel Type Mild Steel

- Steel Product Type Steel Sheets

- Thickness 3 mm , customized

- Shape Customized

- Steel Standard Other

- Click to View more

High Strength Low Alloy Sheets Price And Quantity

- 1 Ton Kilograms

- 56 INR/Kilograms

High Strength Low Alloy Sheets Product Specifications

- Painted, galvanized, or standard mill finish

- 23.55 to 785 kg

- Steel , Silver , Gray

- Customized

- width 1200mm to 2400mm

- Steel

- Other

- Mild Steel

- Steel Sheets

- Construction

- 3 mm , customized

- Steel Products

- Cold-rolled, Hot-rolled or Galvanized

High Strength Low Alloy Sheets Trade Information

- Standard, As per requirement,

- All India

- We are certified under the ISO 9001:2015 standard, with authorized distributor of Memorandum of Understanding (MoU) customer of the Steel Authority of India Ltd. (SAIL).

Product Description

High Strength Low Alloy (HSLA) Sheets

High Strength Low Alloy (HSLA) Sheets are specially designed steel sheets that provide enhanced mechanical properties and superior corrosion resistance compared to standard carbon steel. Unlike conventional steel, HSLA sheets are made with microalloying elements like niobium, vanadium, or titanium, providing improved strength-to-weight ratios without compromising ductility or toughness.

Key Features:

-

Superior Strength: Higher tensile and yield strength compared to standard carbon steel.

-

Weight Reduction: Offers the same strength with less material, making it lightweight and cost-effective.

-

Excellent Formability: Despite higher strength, it maintains good ductility and can be easily formed and fabricated.

-

Improved Corrosion Resistance: Better resistance to atmospheric corrosion due to added alloying elements.

-

Cost-Effective: Reduced weight allows for cost savings in transportation and material usage.

Applications:

-

Automotive Industry: Frames, structural components, chassis, and reinforcements.

-

Construction: Structural beams, girders, and load-bearing components.

-

Shipbuilding: Hulls and structural parts where high strength is essential.

-

Machinery: Parts requiring improved strength and corrosion resistance.

-

Railway Industry: Components such as wagons, coaches, and rail tracks.

Advantages:

-

Higher Strength-to-Weight Ratio: Provides the same structural integrity with reduced material weight.

-

Cost-Efficiency: Less material requirement leads to lower costs.

-

Improved Durability: Enhanced resistance to atmospheric corrosion and environmental stress.

-

Versatility: Applicable across various industries, from automotive to construction.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free