ASTM A36 Angle

Product Details:

- Diameter Length : 6 m, 12 m, or customized lengths

- Recyclable non-recyclable

- Product Name Stainless Steel Products

- Steel Type Stainless Steel

- Steel Product Type Steel Sheets

- Grade ASTM A36

- Thickness From 3 mm to 20 mm

- Click to View more

ASTM A36 Angle Price And Quantity

- 20 Ton

- 57 INR/Kilograms

ASTM A36 Angle Product Specifications

- ASTM A36

- Length : 6 m, 12 m, or customized lengths

- Stainless Steel Products

- Steel Sheets

- 20 x 20 x 3 mm to 200 x 200 x 12 mm

- Stainless Steel

- Customized

- ASTM A36

- Construction

- non-recyclable

- Stainless Steel

- From 3 mm to 20 mm

- Other

ASTM A36 Angle Trade Information

- Standard, As per requirement,

- We are certified under the ISO 9001:2015 standard, with authorized distributor of Memorandum of Understanding (MoU) customer of the Steel Authority of India Ltd. (SAIL).

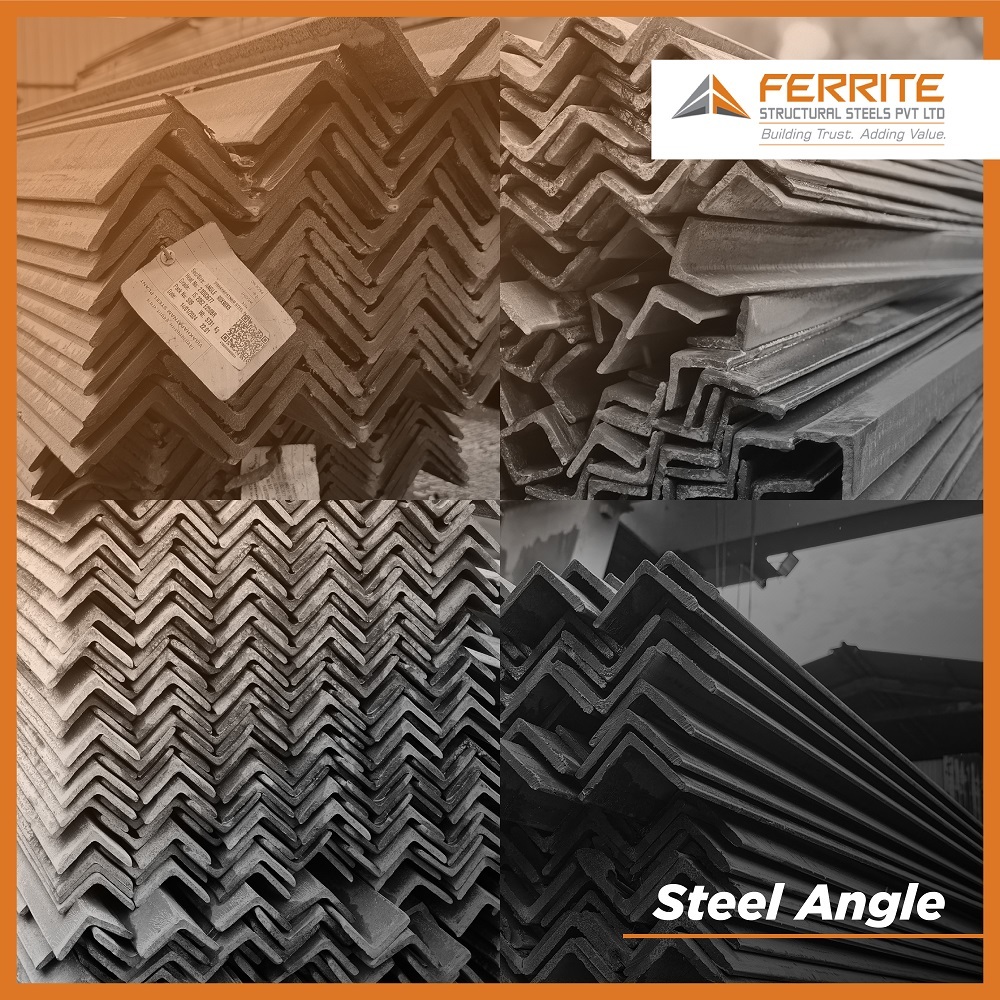

Product Description

ASTM A36 angle steel is a widely utilized structural steel component known for its versatility, strength, and affordability. It is commonly employed in construction, machinery, and various structural applications.‹

Key Features:

-

Composition: This low-carbon steel typically contains a maximum of 0.26% carbon, up to 0.40% silicon, and up to 1.03% manganese. These elements contribute to its weldability, machinability, and formability.‹

-

Mechanical Properties: ASTM A36 steel offers a minimum yield strength of 36,000 psi (250 MPa) and an ultimate tensile strength ranging from 58,000 to 80,000 psi (400-550 MPa). It also exhibits a minimum elongation of 20% over 8 inches (200 mm), indicating good ductility.‹

-

Dimensions: Available in both equal and unequal leg configurations, common sizes range from 20 mm x 20 mm to 200 mm x 200 mm for equal angles, with thicknesses between 3 mm to 20 mm. Lengths are typically offered in 6 m, 9 m, or 12 m, but custom lengths can be accommodated.‹

Advantages:

-

Cost-Effective: Compared to high-strength low-alloy (HSLA) steels, ASTM A36 is more economical, making it a preferred choice for budget-conscious projects.‹

-

Corrosion Resistance: When galvanized, A36 steel angles exhibit enhanced resistance to corrosion, extending their service life in outdoor or humid environments.‹

-

Ease of Fabrication: The material's excellent weldability and machinability allow for straightforward fabrication and assembly in various structural applications.‹

Common Applications:

-

Construction: Utilized in building frameworks, bridges, and support structures due to its strength and reliability.‹

-

Machinery: Employed in the manufacturing of equipment and machinery components where structural integrity is essential.‹

-

Towers: Used in communication and power transmission towers, benefiting from its load-bearing capacity and durability.‹

In summary, ASTM A36 angle steel serves as a fundamental material in numerous structural and industrial applications, offering a balance of strength, versatility, and cost-effectiveness

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free